High Pressure Processing

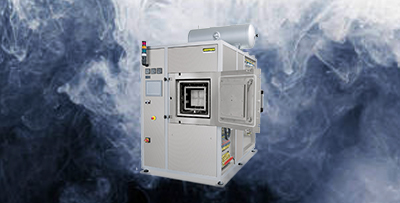

Tanifood is proud to be the first factory to apply HPP (High-Pressure Processing) technology in producing pure fruit juice in Vietnam. This is the world's leading high-pressure processing technology without heat treatment and the first to be used in Vietnam.

HPP (High-Pressure Processing) is a method of food sterilization using water to pressurize the product to between 4,000 to 6,000 Bar (equivalent to pressure of 60,000 meters below sea level) to pasteurize products without additional heat. This ensures no loss of vitamins, flavors or texture of the product.

Advantages

- Compared with heat treatment, HPP processed food will keep a fresher taste; the appearance of the product is aesthetically natural, preserving the structure and nutrients. HPP technology can be controlled at refrigeration temperatures, thus eliminating the risk of high-temperature changes in flavor.

- Products retain sensory qualities including taste, texture, color and nutritional content of newly picked products.

- Meet the most rigorous standards of the US Department of Agriculture (USDA)

- Chemicals or preservative free processing